by Mike OBrien on 03/08/2012

WHAT DO WE DO HERE AT YFS EXACTLY?

A lot of folks are asking us what we do. I figured I'd spell it out exactly for everyone so there's no confusion. Read below for a look into what we're trying to accomplish here at YFS.

We’re often asked about the availability of the custom equipment on our website, and what exactly do we do. First of all, we have day jobs, music and electronics are our passion. Years of designing low noise aerospace electronics, precision instrumentation, professional audio, and consumer electronics have heavily influenced our audio designs. Principles and techniques developed in these disciplines are applied to audio system design. It isn’t a monumental task (though tricky sometimes) to design a reference level amplifier based on design principles developed in the RF communications, instrumentation, and power electronics fields. Many of the preferred topologies and concepts were developed in the 50’s, 60’s, and 70’s. The same can be said of cable design. Many of the standard power supply concepts employed for decades in the instrumentation world are just now finding their way into audio. It amazes me the audiophile community is just figuring out that a power supply influences circuit performance. Some of the lame designs available (at outrageous prices) are appalling. One of the objectives of this website is to show that there is no magic in audio design and many “new” discoveries are resurrections and slight modifications of old designs.

We have been making custom audio electronics for 30 years. The operative word is custom. We have no standard products, just basic designs. I guess we can be thought of as an engineering services house for the audio community. Along with our own designs, we modify, optimize, and repair commercially available equipment.

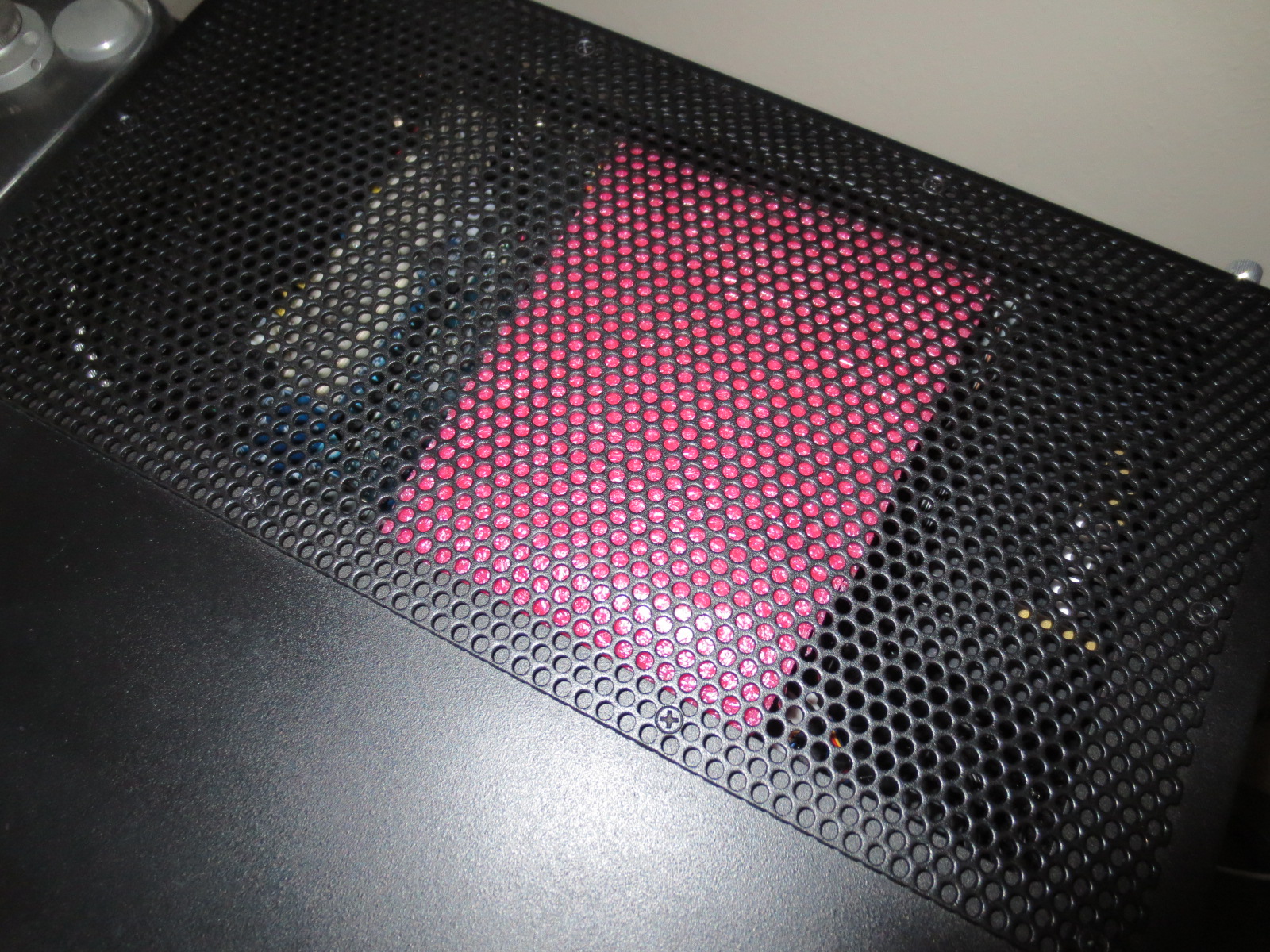

Typically, a customer will audition a circuit in our listening room (with their source and speakers if they choose) to decide what topology they like. They determine the component front and rear panel layouts (number of inputs, functions, controls, style, font, color, height, etc.) for us to build. There have been several cases where the hardware was double the circuit/electronics cost. We understand that aesthetics is often as important to the customer as the sound. To minimize cost and time we build prototypes with minimalist panels (but still presentable) and concentrate on the inside. We have two graphic artists on staff to assist in the aesthetic design if desired.

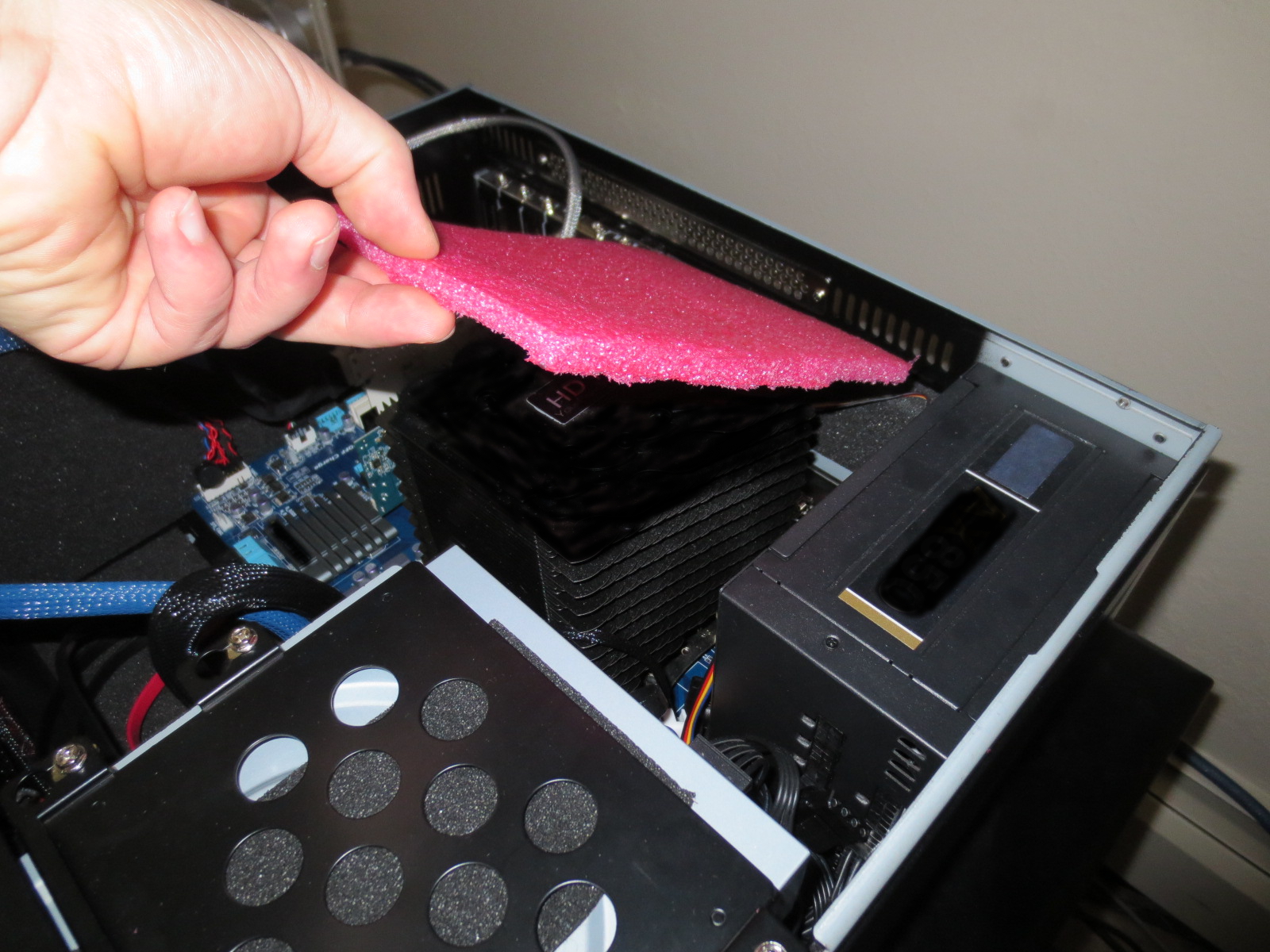

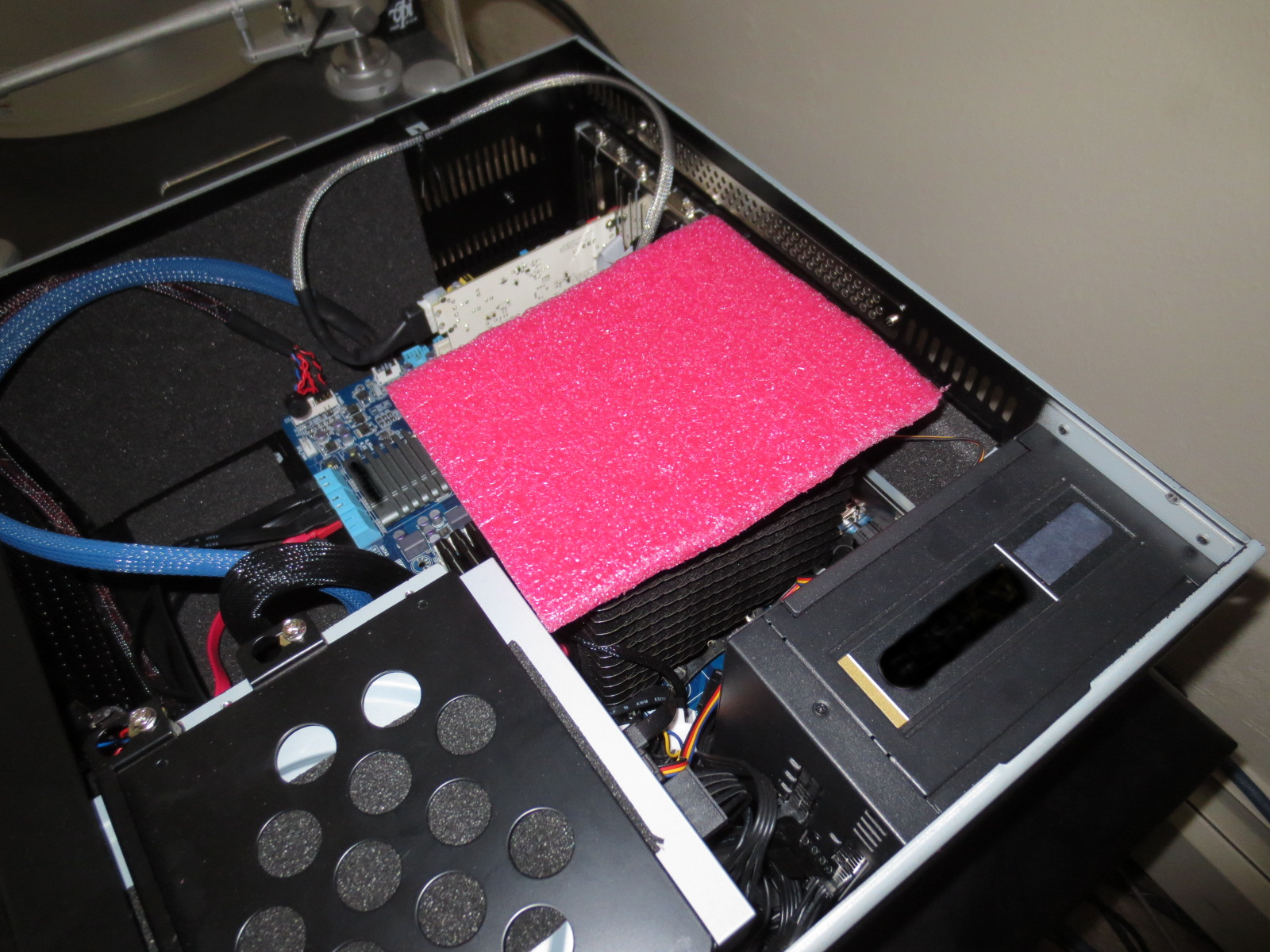

One current project involves designing a preamp with a specific tube the customer picked up at an estate sale (over 50 pristine GE NOS dual triodes). The tube is a little known type with perfect characteristics for audio (nice curves!). Special circuit board materials such as ceramic and Teflon have been employed at the customer ‘s request. We have also sold populated and tested circuit boards to customers who want to build their own cases. On the other hand, we have done the metalwork for other DIY’ers who have built their own boards. This is common with power amp builders where we do the critical heat sink design and power distribution.

Solid-state circuitry is not excluded. We personally like tubes because of the ability to play with the sound by swapping tubes (from different manufactures) or even tube types in some cases. Since we deal with SS designs all day, vacuum tube design is an enjoyable break. We have designed and built many MOSFET and bipolar power amplifiers and preamplifiers. Hybrid power amplifier designs are also popular. Currently available IC’s and transistors have amazing performance compared to what was available in the 70’s. Several of our reference quality discrete designs rivaling tube gear have been designed over the years.

Cables are also a key part of the audiophile system. We use our own interconnects developed from work done in the aerospace and instrumentations fields. There are marginally better cables commercially available with absurd price/performance points. We’ve had several unpleasantly surprised customers that couldn’t tell our cables from their $5000 units they brought to our listening room! We rarely discuss cable design; every manufacturer claims theirs is best for various reasons. We have applied basic physics and engineering to develop cost effective designs using relatively common material. It is amazing what can be done with a little geometry, electromagnetics, and materials science. If there’s an interest, we will post some work done on active shielding and EM noise cancelation for an electron microscope facility.

The least addressed part of the audiophile system is room acoustics. Often a music reproduction system is actually a living room or family room not exactly optimized for sound reproduction. We have designed and built acoustic treatments for several customers to fit into their décor. After analyzing the room (modal, absorption coefficients. etc.) a set of treatments are designed. Our main listening room has an array of diffusers and absorbers to neutralize the room as much as possible. Customers are amazed at the difference in imaging and overall frequency response of their speakers in a properly treated room. Our acoustics experience extends to speaker design. We have developed several sets of reference speakers (to technically challenge ourselves), but we have our favorite commercial units (Acoustic Zen, and Von Schweikert) we use as references. We have no desire to build speakers, not even another set for ourselves! :-)

If you’re interested in how we come up with our designs or just want to chat, we’re here to help! Drop us a line and we’ll be glad to design/ build your dream component or just help you with anything audio related. When we say we’ll help, we mean it.

-MOB